Vian Nexus EVO 7 kW EVI Heat Pump

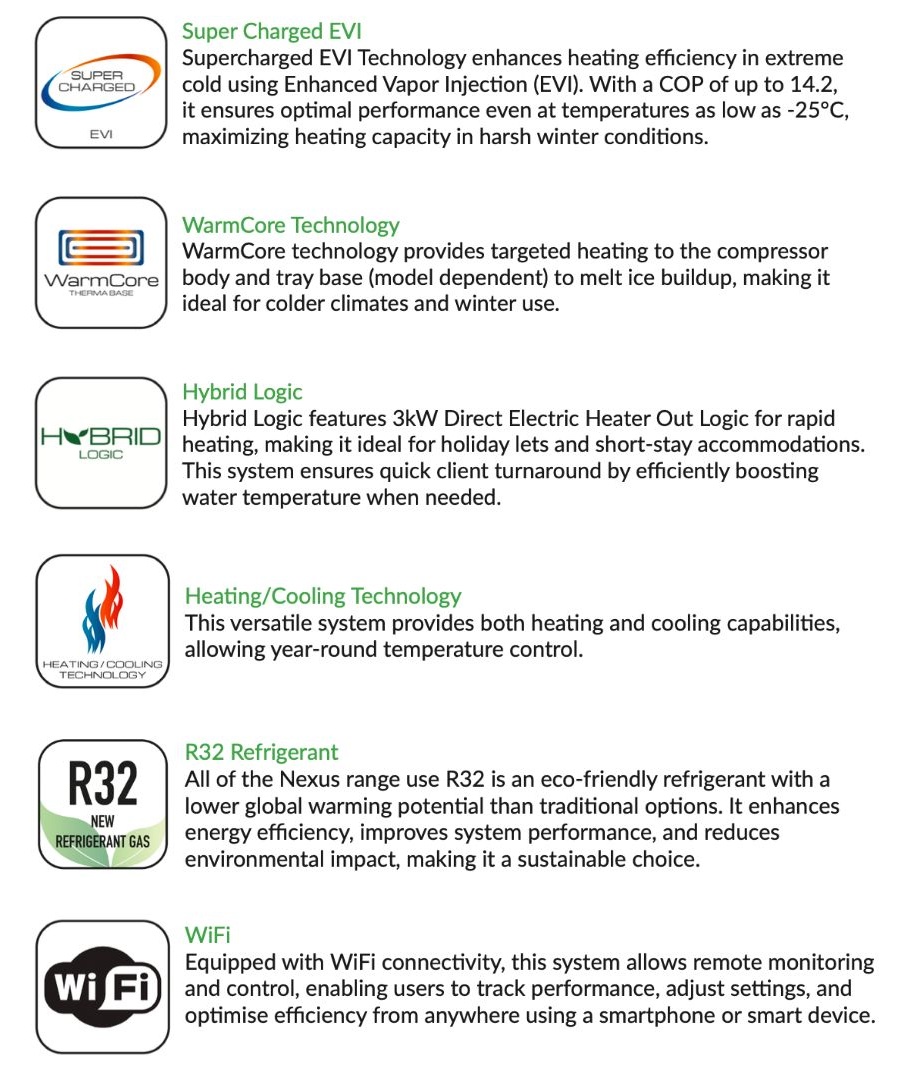

The Nexus 7 EVI, the flagship model of the range, is built for extreme climates. With Enhanced Vapor Injection (EVI) technology, it achieves a COP of up to 14.2 and operates efficiently down to -25°C, delivering maximum heating in extremely low temperatures. The Nexus Heat Pump Steps offer easy access and a sleek cover for the unit.

* Price is subject to survey

Description

- Supercharged EVI Technology, for enhanced heating efficiency in extreme cold.

- Operates down to -25°C, for reliable performance in freezing conditions.

- Nexus Communication, that can interpret and respond to latest Balboa control signals.

- Hybrid Logic, 3kW Direct Electric Heater Out Logic.

- Input Switch for Gecko In.Grid & Balboa Relay.

- WarmCore heating to compressor body and tray base to melt ice build-up.

HOW DOES EVI WORK?

HOW DOES EVI WORK?

EVI technology functions like a supercharger in a car engine. A standard heat pump (EEV) operates well under normal conditions but struggles in extreme cold.

EVI “supercharges” the refrigerant cycle by injecting extra vapour at an intermediate stage, increasing heating capacity and efficiency, even in freezing temperatures.

This results in more reliable heating performance, lower energy costs, and greater durability of the heat pump.

EVI vs EEV

Cold Weather Performance

EEV Compressor: Efficiency drops below -10°C.

EVI Compressor: Maintains efficiency down to -25°C.

Heating Power Output

EEV Compressor: Reduced at low temperatures.

EVI Compressor: Higher heat output in extreme cold.

Longer Compressor Lifespan

EEV Compressor: Decreases in freezing weather.

EVI Compressor: Higher COP, even in sub-zero conditions.

More Reliable Heating Performance

EEV Compressor: Works harder in cold.

EVI Compressor: Reduced strain, resulting in longer lifespan.

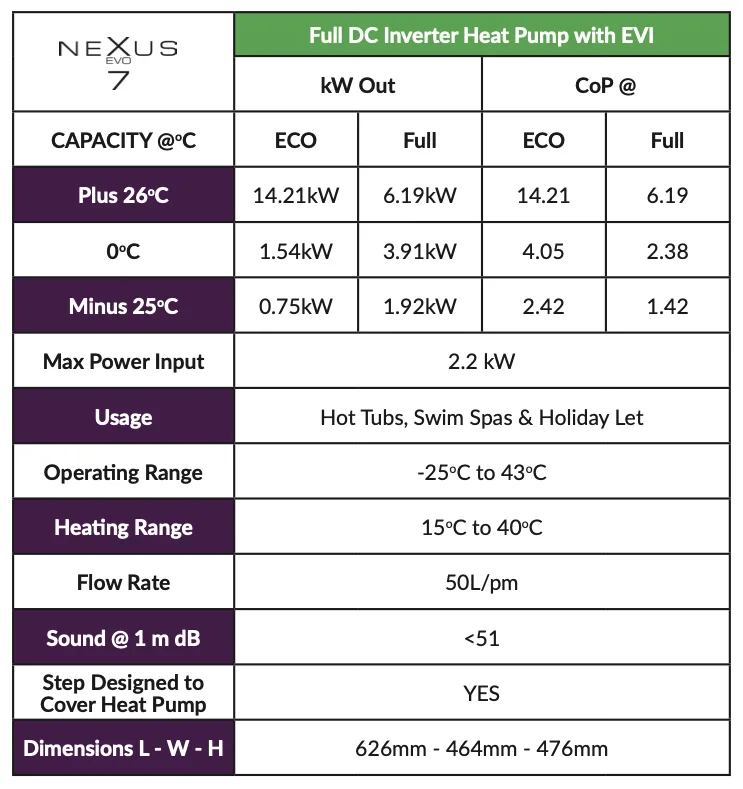

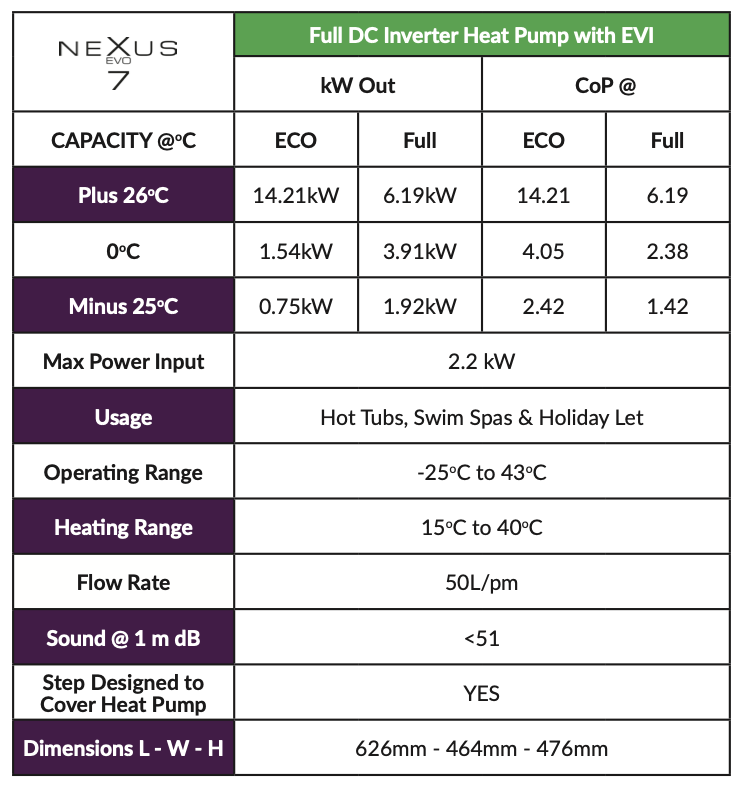

Specification

HOW DOES AN AIR SOURCE HEAT PUMP WORK?

The fan in the air source heat pump draws air over a network of tubes that look a little like a car radiator. These tubes are filled with an eco-friendly R32 refrigerant. The air then passes over the tubes warming up the refrigerant and turning it from a liquid into a gas.

This gas is passed through a compressor which increases the pressure and significantly raises the temperature of the gas, which is then passed through a titanium heat exchanger.

The swim spa or hot tub’s water circulation system is plumbed through the air source heat pump and the heat from the gas travels through the heat exchanger, which in turn heats the water from the hot tub or swim spa as it passes over it. The refrigerant then cools and turns back into a liquid and starts the process all over again.

Not only is this a far more cost-effective solution to heat your hot tub or swim spa, but it is also a much more eco-friendly option.

HOW DOES AN AIR SOURCE HEAT PUMP WORK?

The fan in the air source heat pump draws air over a network of tubes that look a little like a car radiator. These tubes are filled with an eco-friendly R32 refrigerant. The air then passes over the tubes warming up the refrigerant and turning it from a liquid into a gas.

This gas is passed through a compressor which increases the pressure and significantly raises the temperature of the gas, which is then passed through a titanium heat exchanger.

The swim spa or hot tub’s water circulation system is plumbed through the air source heat pump and the heat from the gas travels through the heat exchanger, which in turn heats the water from the hot tub or swim spa as it passes over it. The refrigerant then cools and turns back into a liquid and starts the process all over again.

Not only is this a far more cost-effective solution to heat your hot tub or swim spa, but it is also a much more eco-friendly option.